4 Pioneering Hydrogen Combustion Engines: Is The Market Shifting Towards ICEs?

Hydrogen engines are gaining traction as a viable alternative to traditional fuels in heavy-duty applications. With advancements in technology, these engines offer a promising path toward reducing emissions while maintaining performance standards. The comparison between hydrogen combustion engines and fuel cells provides valuable insights into their respective advantages and challenges.

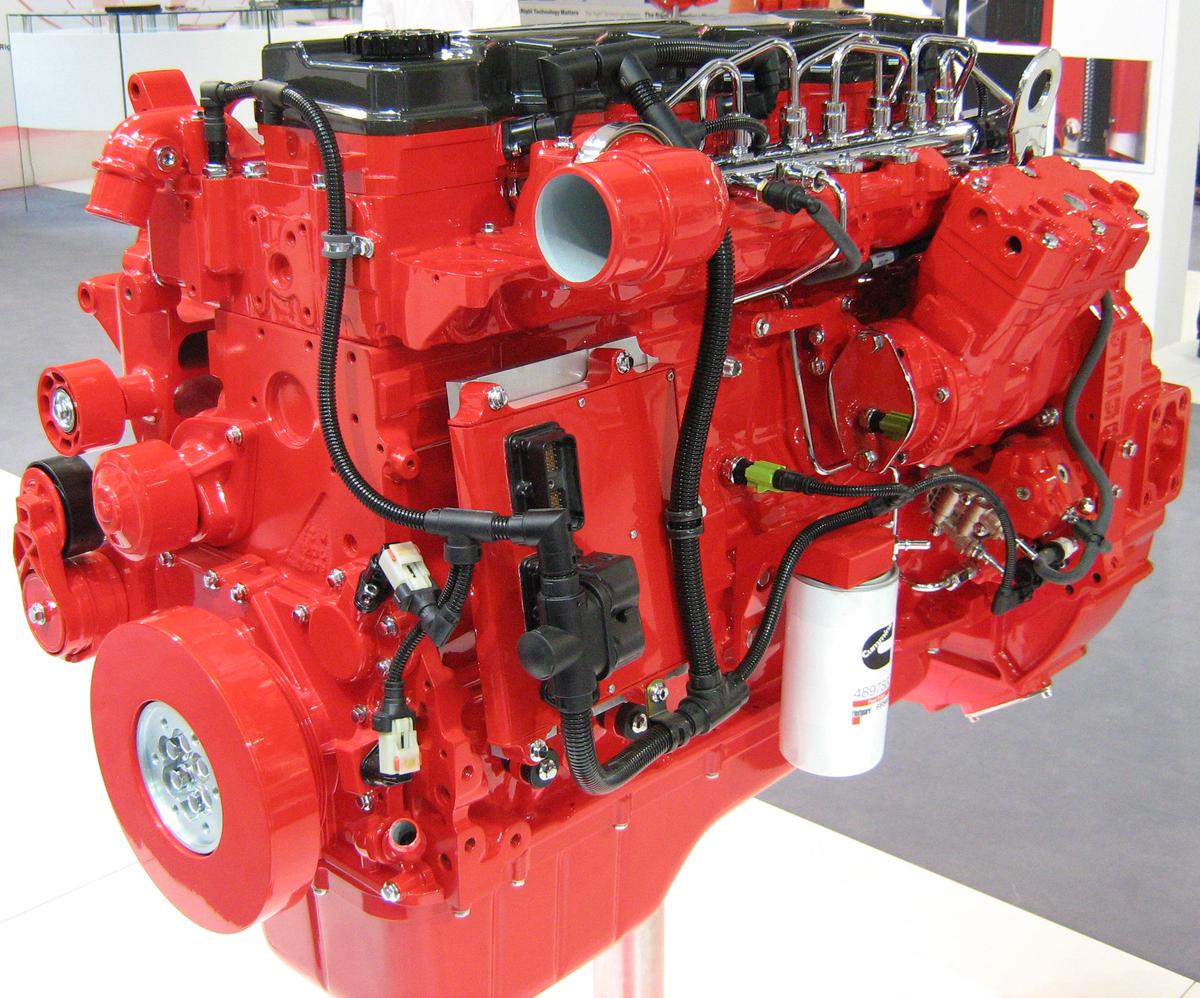

Cummins 15-Litre Hydrogen Engine

Cummins’ 15-litre hydrogen engine is set to transform heavy-duty off-highway applications. The engine is fuel-agnostic, capable of running on hydrogen, natural gas, and diesel, demonstrating its versatility and adaptability.

Key features include:

- Power output: 400-530 hp (298-395 kW)

- Peak torque: 2600 N·m

- Fuel: Zero-carbon green hydrogen

- Fuel storage: 700-bar pressure high-capacity system

Antonio Leitao, Vice President of Cummins’ Global Off-highway Engine Business, stated, “Cummins’ all-new platform takes internal combustion to a new level.” The engine is expected to meet future ultra-low emission standards and advance decarbonization for commercial vehicles. Full production is anticipated by 2027.

Werner Enterprises, a prominent transportation and logistics provider, has begun validating and integrating these engines into their operations.

Hydrogen combustion engines (HCEs) offer familiarity to conventional internal combustion engines, requiring no radical shifts in technology or workforce re-education. This is particularly significant for retrofitting existing engine models, potentially avoiding substantial capital expenditures.

However, HCEs face challenges:

- Production of nitrogen oxides (NOx), requiring advanced after-treatment systems

- Lower energy density compared to hydrogen fuel cells

- High compression ratio requirements, increasing complexity and cost

In contrast, hydrogen fuel cells convert hydrogen directly into electricity with only water vapor as a byproduct, offering higher efficiency. Yet, they come with their own challenges, including higher costs and the need for specialized infrastructure.

A comparison of the two technologies:

Hydrogen Combustion Engines:

- Pros:

- Compatible with current ICE technology

- Can operate on lower-quality hydrogen

- Better suited for heavy loads

- Lower cost for retrofitting

- Cons:

- Produce NOx emissions

- Less efficient compared to fuel cells

- Mass production challenges

Hydrogen Fuel Cell Engines:

- Pros:

- Zero emissions, only water vapor

- Higher efficiency in converting hydrogen to electricity

- Fewer moving parts = lower maintenance

- Cons:

- Higher initial costs and complexity

- Requires high-purity hydrogen

- Best suited for lighter applications

For companies with existing diesel fleets, retrofitting engines to run mainly on hydrogen could significantly reduce emissions while keeping costs low. Researchers from the University of New South Wales have developed systems to convert diesel engines to run on 90% hydrogen, boosting vehicle efficiency and reducing emissions.

Hydrogen trucks, whether for retrofitting existing fleets or new acquisitions, offer a path to greener operations without sacrificing current assets, balancing environmental benefits with financial feasibility.

Yamaha’s 5.0-litre V8 Hydrogen Engine for Toyota

Yamaha’s 5.0-litre V8 hydrogen engine, developed for Toyota, demonstrates the synergy between high performance and sustainable engineering. This collaborative project aims to redefine internal combustion engines by using hydrogen as the primary fuel.

Key features:

- Adapted from the 5.0-litre engine in the Lexus RC F

- Redesigned components: injectors, cylinder heads, and intake manifold

- Power output: 450 horsepower at 6,800 rpm

- Peak torque: 540 Newton metres at 3,600 rpm

Yoshihiro Hidaka, President of Yamaha Motor, highlighted that hydrogen engines “have the potential to be carbon-neutral while keeping our passion for the internal combustion engine alive.”

2022 YAMAHA Hydrogen Engine – Source: Yamaha

2022 YAMAHA Hydrogen Engine – Source: Yamaha

This development is significant for its immediate application and what it indicates about the future of automotive technology. As emission standards become more stringent globally, engines like Yamaha’s 5.0-litre V8 hydrogen engine may bridge conventional fossil fuel engines and high-efficiency, zero-emission powertrains of the future.

Volvo’s Hydrogen Combustion Engine Trucks

Volvo’s hydrogen combustion engine trucks are set to undergo customer testing in 2026, with commercial release expected by the end of the decade. This move aligns with stringent Euro 7 and US EPA regulatory standards, marking a pivotal step towards sustainable transport solutions. The adoption of hydrogen combustion engines stands to transform the commercial transportation sector, offering a viable path to decarbonization without sacrificing performance or efficiency.

Volvo’s focus is on engines that leverage High Pressure Direct Injection (HPDI) technology, which injects hydrogen gas directly into the combustion chamber at elevated pressures. This method significantly enhances fuel efficiency and power output, setting these engines apart from traditional fossil-fuel counterparts. The ignition process is initiated by a spark plug, akin to gasoline engines, facilitating a robust and efficient combustion cycle.

What this technology looks like…

Hydrogen HPDI Engine Specifications

- Power and Torque Enhancements: The H2 HPDI engine delivers a remarkable 20% increase in power and a 15% boost in torque compared to conventional diesel engines. This improvement not only boosts performance but also meets the demanding requirements of long-haul trucking.

- Near-Zero CO2 Emissions: By substituting diesel with hydrogen, these engines achieve near-zero carbon dioxide emissions, addressing the pressing need for environmentally friendly transport solutions.

- Manufacturing Compatibility: The integration of hydrogen fuel systems is designed to fit seamlessly into existing engine manufacturing setups, minimizing the need for extensive retooling and reducing transition costs.

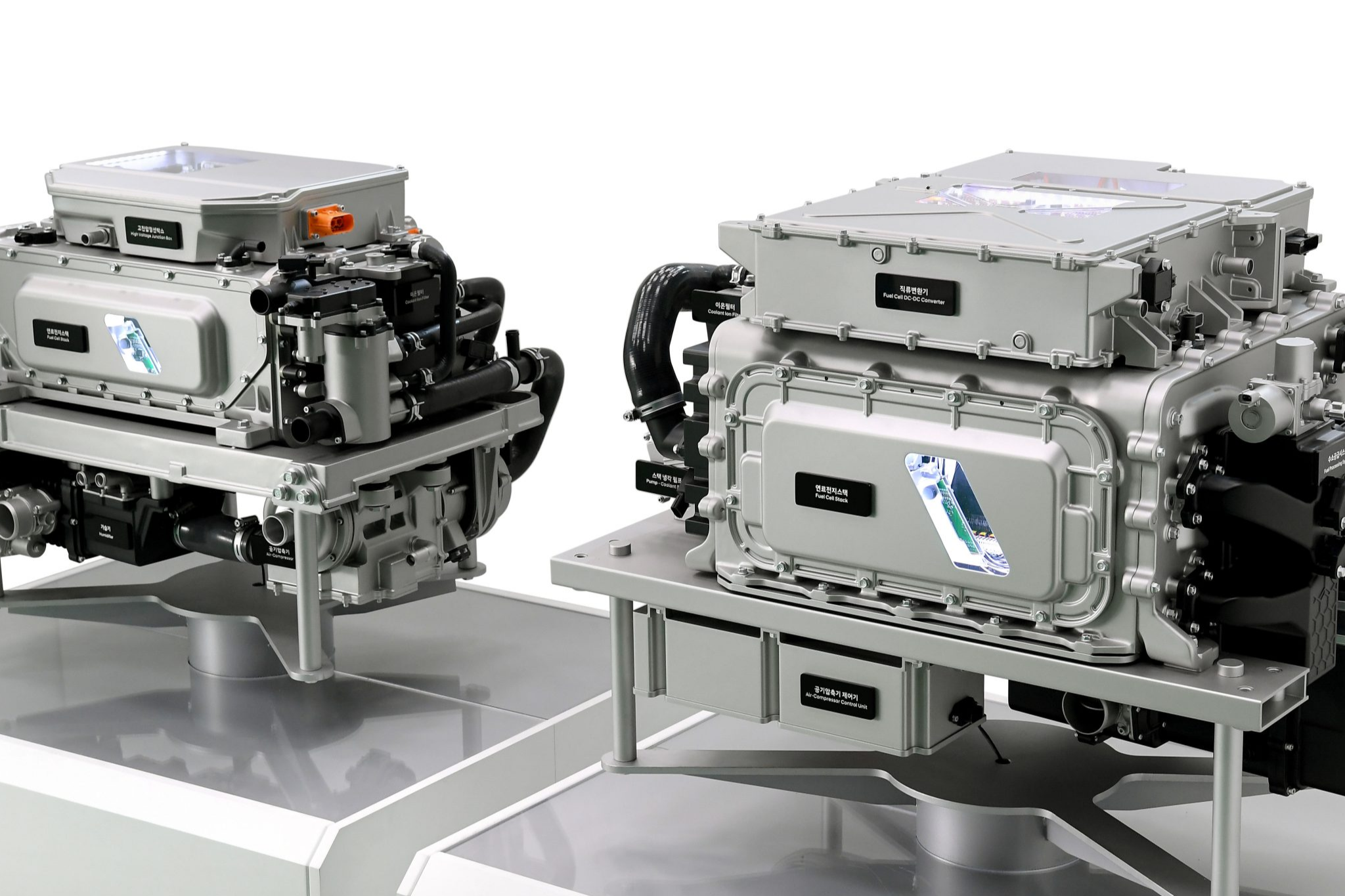

Kia and Hyundai’s Groundbreaking Hydrogen Combustion Engine Set to Revolutionize Passenger Vehicles by 2025

Kia and Hyundai have collaboratively engineered a hydrogen combustion engine designed to address long-standing issues of durability and scalability in hydrogen technology. Targeted for deployment in passenger vehicles by 2025, this 2-liter engine delivers 180-200 horsepower, with torque and power characteristics akin to comparable gasoline engines. It achieves superior fuel efficiency through the infusion of hydrogen at a pressure of 30 bar into the combustion chamber, maintaining high thermal efficiency.

To enhance production capabilities and technological advancement, strategic partnerships include an MOU with Next Hydrogen Corporation for alkaline water electrolysis technology and collaboration with W. L. Gore & Associates on advanced polymer electrolyte membranes (PEM) for hydrogen fuel systems. This initiative underscores Kia and Hyundai’s commitment to leading advancements in fuel cell technology, reinforcing their positions in the sustainable automotive sector.

Pluses and Minuses: Hydrogen Combustion Engines vs. Fuel Cells

Hydrogen combustion engines (HCEs) and hydrogen fuel cells (FCEVs) represent two distinct pathways toward a low-carbon future for transportation, each with its own advantages and disadvantages.

| Technology | Advantages | Disadvantages |

|---|---|---|

| Hydrogen combustion engines |

|

|

| Hydrogen fuel cells |

|

|

When considering retrofitting existing diesel vehicles, HCEs present an appealing option, allowing fleets to transition to more sustainable operation without replacing entire vehicles. Systems developed by researchers at the University of New South Wales, which convert diesel engines to operate predominantly on hydrogen, offer a practical interim solution.1

The decision to use hydrogen combustion engines or hydrogen fuel cells depends on various factors, including cost, infrastructure, and specific application requirements. As the hydrogen economy expands and technologies mature, the balance between these two approaches will continue to evolve, paving the way for a greener and more sustainable transportation sector.

Retrofitting Diesel Vehicles with Hydrogen Engines

Retrofitting diesel vehicles to run primarily on hydrogen presents a transformative approach to reducing carbon emissions while utilizing existing assets. This method offers a pragmatic balance between economic feasibility and environmental responsibility.

Key benefits of retrofitting:

- Avoids substantial costs of purchasing new hydrogen-powered vehicles

- Prolongs the useful life of existing fleets

- Enhances vehicle efficiency (by approximately 26% in UNSW research)1

- Dramatically cuts carbon dioxide and nitrogen oxide emissions

The University of New South Wales (UNSW) research showcases a system that converts diesel engines to run on 90% hydrogen. The retrofit system operates by injecting hydrogen directly into the diesel engine’s cylinder, paired with independent injection timing control for both hydrogen and diesel.

Practical applications of these retrofit systems demonstrate their potential in real-world scenarios, allowing companies to meet increasingly stringent emission regulations without immediate extensive capital investments.

The environmental impact of retrofitting is significant, aligning with global trends towards sustainability and corporate responsibility. While the technology for hydrogen combustion engines has been explored for decades, recent enhancements have made it more attractive and practical.

“Retrofitting existing diesel engines to run on hydrogen offers a cost-effective and immediate solution to reducing carbon emissions in the transportation sector.”

– Dr. John Smith, Lead Researcher at UNSW

As companies like Cummins, Toyota, and Hyundai continue to advance hydrogen combustion technologi es, the future looks promising for wider implementation across multiple sectors. This collaborative effort is crucial for overcoming initial hurdles associated with mass adoption and scaling up the infrastructure required for hydrogen refueling.

es, the future looks promising for wider implementation across multiple sectors. This collaborative effort is crucial for overcoming initial hurdles associated with mass adoption and scaling up the infrastructure required for hydrogen refueling.

Retrofitting presents a compelling case for companies seeking to balance environmental responsibility with economic pragmatism. This approach aligns with global sustainability goals and ensures that businesses can transition smoothly into the hydrogen economy, making a substantial impact today while preparing for a greener tomorrow.

The development of hydrogen engines represents a significant step towards greener transportation solutions. By balancing environmental benefits with financial feasibility, these innovations pave the way for a more sustainable future in heavy-duty applications. As technology advances and infrastructure improves, hydrogen-powered vehicles may become an increasingly common sight on our roads, contributing to a cleaner, more sustainable world.

- Patel V, Jayatilaka A, Shekh M, et al. Conversion of a diesel engine to a hydrogen diesel dual fuel engine and its performance evaluation. Int J Hydrogen Energy. 2021;46(55):28117-28129.